Model:

| Model |

Shank diameter |

Length |

Pcs/Stick |

Pcs/Box |

Boxes/Carton |

| inch |

mm |

| ST15 |

2.18mm(14Gauge) |

15mm |

5/8″ |

40 |

1000 |

10 boxes/20 boxes |

| ST18 |

18mm |

3/4″ |

40 |

1000 |

10 boxes/20 boxes |

| ST25 |

25mm |

1″ |

40 |

1000 |

10 boxes/20 boxes |

| ST32 |

32mm |

1-1/4″ |

40 |

1000 |

10 boxes/20 boxes |

| ST38 |

38mm |

1-1/2″ |

40 |

1000 |

10 boxes/20 boxes |

| ST45 |

45mm |

1-3/4″ |

40 |

1000 |

10 boxes/20 boxes |

| ST50 |

50mm |

2″ |

40 |

1000 |

10 boxes/20 boxes |

| ST57 |

57mm |

2-1/4″ |

40 |

1000 |

10 boxes/20 boxes |

| ST64 |

64mm |

2-1/2″ |

40 |

1000 |

10 boxes/20 boxes |

Applicable tools:

Compatible Nail Systems

This product is designed to match the most common T-type trim nail standards used in international markets and is:

Equivalent to: DUO-FAST TN series,SENCO “T” series,ATRO “TN22″,Meite “ST” series,Omer TN22,Aerosmith “Trim Pins”,Grip-Rite Concret T nails.

| Brand |

Tools |

| Meite |

ST64, |

| Freeman |

PCTN64 |

| Air Locker |

CN64A3 |

Spotnails

|

M1T9764 |

| Omer |

TN64,TN732 |

| Grex |

2564 |

| Akdeniz |

ST38-C,2264 |

| Senco |

TPRO 65 |

Application:

Concrete T nails are designed for fast and secure fastening into concrete, masonry, and steel substrates when used with compatible T-type nailers.

Typical applications include:

• Fixing wood strips, furring strips, and battens to concrete or masonry walls

• Securing plywood, panels, and boards onto concrete or steel bases

• Fastening metal channels, brackets, or clips in light to medium-duty construction

• Interior finishing applications such as trim installation, framing, and renovation work

• Industrial and commercial projects requiring high holding strength and consistent penetration

Concrete T nails are widely used in construction, interior finishing, remodeling, and industrial installation where speed and reliability are required.

Concrete T Nails – FAQ (For Wholesalers & Importers)

1. What are concrete T nails mainly used for?

Concrete T nails are used for fastening wood, plywood, metal channels, and wire lath to concrete, masonry, and steel surfaces using compatible T-type concrete nailers.

2. What tools are concrete T nails compatible with?

Concrete T nails are designed for T-type concrete nailers, compatible with systems such as DUO-FAST TN, SENCO “T”, Grex, and similar tools, depending on nail length and gauge.

3.What gauge are concrete T nails?

Most concrete T nails are manufactured in 14 gauge, offering a balance of penetration strength and holding power for concrete and steel fastening.

4. What surface finishes are available?

Available finishes include bright and galvanized for improved corrosion resistance. Other finishes can be customized upon request.

5. Can concrete T nails be customized?

Yes. Customization is available for:

• Nail length and shank diameter

• Surface finish

• Packaging type and labeling

• OEM and private label requirements

6. Are concrete T nails glue collated?

Yes. Concrete T nails are commonly glue-collated in strips, allowing smooth feeding and efficient operation in pneumatic T-nailers.

7.What materials are used for concrete T nails?

Concrete T nails are made from hardened 1045/1055 steel, with heat treatment to ensure consistent hardness and reliable penetration.

Additional Services

To support wholesale buyers and long-term partners, we provide the following additional services for concrete nails:

• Customized packaging and labeling according to customer requirements, including private label and OEM solutions

• Consistent surface finish and appearance control across production batches to ensure uniform quality for bulk supply

• Export documentation support, including packing list preparation and HS code declaration for international shipments

• Stable supply capability for bulk orders with confirmed specifications, ensuring on-time production and delivery

• OEM and private label support for distributors, wholesalers, and brand owners

Why Choose Us?

1.Experienced Manufacturer

With over 20 years of manufacturing experience, we specialize in the production of concrete nails and industrial fasteners for international markets.

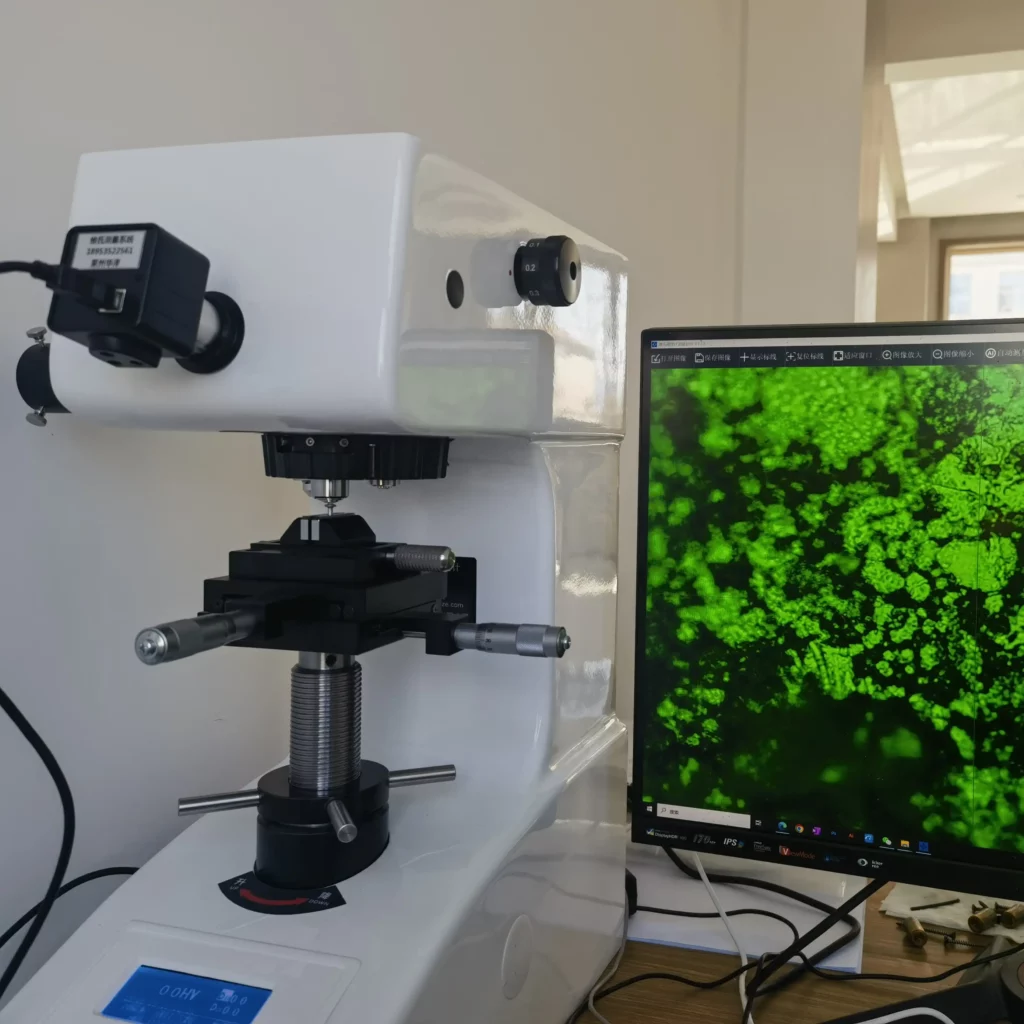

2.Complete Quality Control System

From wire drawing to finished nails, every production stage is monitored with dedicated inspection equipment. Hardness testing, dimensional checks, and process control ensure stable and consistent quality.

3.In-House Production & Stable Capacity

Equipped with cold heading machines, heat treatment lines, and surface finishing facilities, we support continuous production and reliable supply for bulk and repeat orders.

4.Flexible OEM & Customization Support

We offer customization in size, surface finish, packaging, and private labeling to meet different market and customer requirements.

5.Export-Oriented Supply Experience

Familiar with export standards, packing specifications, and international logistics, we provide efficient support for wholesalers, distributors, and long-term partners.

Manufacturing Facility & Quality Control

Selected views of our production process, quality inspection, and shipment preparation for wholesale orders.