Why Do Different Materials Need Completely Different Screws

The world of building and making things depends on solid links, from fixing drywall ceilings to steel beams to bolting big machines onto concrete floors. Ever grab a pack of screws and feel lost with all the kinds? Folks in the trade learn quick that picking the wrong one strips threads, cracks wood, or worse, causes a collapse. It all comes down to how stuff works at a tiny level. The screw has to play nice with whatever it’s going into, be it soft pine lumber, tough concrete blocks, or skinny sheet metal panels.

For folks handling big orders and sales, nailing this choice cuts hours and cash wasted on the job site. That’s when a good supplier steps in big time. For years, Qinjia has backed up builders and sellers from North America clear to Australia. They do more than ship boxes; they tweak screws for building frames and wood joints, keep stock flowing steady, and stick to tough quality rules. Their setup runs checks on every step, starting with raw steel coils up to the packed crates ready to go.

Do Thread Pitches and Depths Really Matter for Substrates?

You bet they do. Threads are what keep the screw from popping out under weight. Picture a boot sole on muddy ground; the pattern must fit the dirt to grab hold. A screw built for squishy stuff spins loose in metal, and the opposite happens too. It boils down to how much contact area the threads get and how they shove material aside without wrecking the spot.

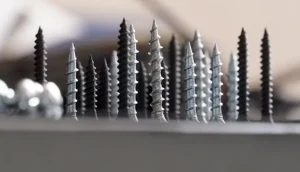

Fundamental Difference Between Coarse and Fine Threads

Check a coarse thread up close. The grooves run deep, and spaces between them stretch wide. This setup works great in soft stuff like pine boards or drywall sheets because it grabs a bunch of material. Fine threads sit shallow with lots crammed close together. They suit metal better. Metal packs tight, so extra threads in a short span bite in without cracking the thin steel around the hole.

How Thread Design Creates Holding Power and Prevents Stripping

Good threads carve matching grooves in the base as you twist the screw in. In wood, big gaps in coarse threads let sawdust escape, so the screw turns easy and avoids splitting the grain. Stick a fine thread in soft wood, and fibers give way fast, stripping the hole clean. For gypsum board jobs, special threads lock in for good.

Qinjia’s Drywall Screws for Gripping

Picking right matters a ton in wall systems today. Drywall screws for attaching boards to frames split into coarse for wood studs and fine for light steel ones. Coarse ones dig far into wood. Fine ones cut into metal without bending the slim gauge. Qinjia’s drywall screws come with sharp edges and even make for quick drives and firm links in wood or metal setups.

Should a Screw Be Designed to Drill or to Tap?

It depends on saving time versus joint strength. Projects trade speed for solid builds. Some bases stay too hard; you drill first before screwing. Others get a sharp point that carves its path, skipping the drill step.

Self Tapping Screws and Pre Drilled Holes

Machine screws often need a tapped hole or nut since they join prepped parts without cutting new paths. But many build screws tap their own threads for faster work. A small pilot hole helps, yet the screw handles the rest.

When Self Drilling Is Absolutely Essential for Speed

Top speed hits with self-drilling types. Their tips look like tiny drill bits, boring and threading in one go. On big wood frame jobs, skipping drills saves bucks per minute. Concrete needs pre-drills always, but softer stuff loves self-drilling perks.

The Unique Design of Qinjia’s Chipboard Screws

Particle board, MDF, or cabinet woods demand quick installs without cracks. Chipboard screws get special threads to slide in smooth, holding tight without harming board edges. Furniture builders and cabinet shops worldwide count on them.

Why Is the Head Style a Crucial Part of the Connection?

Heads aren’t just looks. They handle drive tools, spread weight, and finish the surface. The shape picks the driver bit like Phillips or square, and sets torque limits. It also controls how the screw sits and clamps parts.

The Functional Purpose of Bugle Heads and Countersinks

Bugle heads on drywall screws dip a bit into the paper cover without ripping it. They leave a small dip easy to fill with mud or paint for flat walls. A plain flat head tears paper and weakens grip.

Distributing Load with Pan Heads and Hex Heads

Some heads rest on top to share pull forces. Pan and hex types give wide bases under the head, key for metal brackets or heavy loads. This stops pull-through in soft or thin stuff. Big hex heads scream high torque, like on lag bolts or masonry pins.

Achieving a Smooth Finish with the Bugle Head Drywall Screw

Bugle heads rule interior walls. After fixing board to stud with coarse in wood or fine in metal, you get a gentle dip ready for tape and paint. This speeds clean results in walls and ceilings.

How Does Material Hardness Influence Screw Composition?

Soft pins bend in hard concrete, plain and simple. Screws must out-harden what they enter or they snap or dull. This shifts from shape to metal makeup.

Necessity of High Carbon Steel for Hard Substrates

Concrete or brick pins use high-carbon steel with heat treats. This builds hardness and stretch strength to punch dense walls without shank breaks. Regular wood screws fail right away.

Choosing Appropriate Coatings for Corrosion Resistance

Setting picks the cover. Indoor drywall gets black phosphate for slip and light rust guard. Outdoor deck or concrete nails need zinc plate or blue finish against water. Qinjia supplies these for wet or dry spots worldwide.

Qinjia’s Quality Assurance and Hardness Testing Process

Real makers test, no guesses. Qinjia uses gear like thread speed testers and hand torque tools on screws. They run hardness checks and salt spray runs often. This covers raw wire to shipped boxes, giving dealers peace of mind.

Are Specialized Screws Required for Composite Materials?

Fake woods like particle board or MDF act odd compared to real lumber. Denser yet crumbly at edges, they challenge screws.

Addressing Splitting and Swelling in Particle Board and MDF

Standard wood screws push too hard in particle board; bits crumble, joints weaken. Edges split easy near sides.

The Importance of a Dedicated Thread for Chipboard Applications

Chipboard screws stay slimmer with custom pitch for dense yet brittle boards. They enter gentle, cut split risk, keep cabinet strength.

Recommended Usage Scenarios for Qinjia’s Chipboard Screw

Use in cabinets, furniture builds, or shelves from fake wood. Design gives lasting links where regular screws damage or fail.

Can One Screw Type Truly Be Universal Across All Applications?

If one fit all, stores wouldn’t stock thousands. Nice dream, but no go in real builds.

The Myth of The All Purpose Fastener

No screw packs steel strength, fine machine threads, drywall bugle, and deck rust proof in one. Each trait trades off another. Wrong pick costs rework and risks over cheap bulk buys.

When Compromise Leads to Structural Failure and High Cost

Drywall screw in frame wood pulls loose under weight. Thick masonry pin in trim splits finish. Tiny price gap pales next to fix-up hours or collapse claims.

Partnering with Qinjia for Complete Custom Fastening Solutions

Picking right needs know-how, tests, and steady supply. From ST nails in frames, drywall in finishes, to chipboard in furniture, get app-fit quality. For global stock and OEM/ODM, hit up Qinjia.

FAQ

Q1: What is the main difference between coarse thread and fine thread screws?

A: Coarse threads run deep with wide spaces, made to grab soft stuff like wood or drywall. Fine threads stay shallow and packed tight, good for dense or thin metal like steel studs.

Q2: Can I use a standard wood screw in particle board?

A: Better grab a chipboard screw. Regular ones push out too much, causing splits or crumbles in particle board or MDF, ending in weak spots.

Q3: What makes a screw self-drilling?

A: Self-drilling screws sport a drill-bit tip. It cuts the hole and threads in one quick twist, no extra drill needed.