Top 5 Application Scenarios of Coil Nails

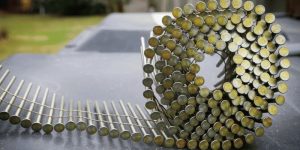

When you run a busy factory or handle big construction jobs, nothing beats coil nails for getting work done fast and strong. These handy fasteners come joined together in long coils, often holding 225 to 400 pieces each, so your team spends less time loading and more time building. Located in Hebei, China, Qinjia has spent over ten years perfecting coil nails for customers worldwide. The company ships top-grade coil nails to buyers in North America, Australia, the Middle East, Southeast Asia, and Turkey. You can pick ring shank, screw shank, or smooth shank styles, plus different levels of galvanizing to fight rust. Thanks to full OEM/ODM support and careful quality checks, Qinjia makes sure every order arrives exactly as promised.

What Makes Coil Nails Essential for Modern Fastening Needs?

Deadlines keep getting tighter, and labor costs keep climbing. Coil nails step in and fix both headaches at the same time.

High-Speed Production Compatibility

A single coil slides into the gun in seconds and keeps firing for several minutes. One worker easily outruns a whole crew swinging hammers.

Superior Holding Power Options

Ring shank and screw shank versions grip wood much tighter than smooth ones, often by 30-50 percent. Heavy loads and constant shaking cannot pull them out easily.

Versatile Material and Finish Choices

Bright finish works indoors. Electro-galvanized, mechanical galvanized, or hot-dipped versions stand up to rain, salt air, and tough weather for many years.

Revolutionizing Pallet Manufacturing with Coil Nails

Pallet factories live or die by daily output. Even a short pause to reload nails eats profit fast.

Streamlined Assembly Lines

Diameters from 2.1 mm to 3.8 mm and lengths reaching 130 mm let pneumatic nailers fire non-stop. Factories regularly boost daily production by 30-50 percent once they switch to coil nails.

Enhanced Durability for Global Shipping

Hot-dipped galvanized coil nails laugh at salty ocean air. Export pallets stay solid from factory floor to final destination, and they meet strict international standards without trouble.

Cost-Effective Bulk Packaging

Big cartons holding 400 coils each cut down on trash and keep the workshop tidy. Your team grabs a fresh coil quickly and gets right back to work.

Building Robust Timber Frame Structures Using Coil Nails

Wood-frame builders need speed on site and strength that lasts for decades.

Secure Framing Connections

Full round head coil nails with sharp diamond points bite deep and hold tight. Tensile strength stays above 600 N/mm², so walls, floors, and roofs stay exactly where they belong.

Weather-Resistant Performance

Screw shank nails coated with electro-galvanized or hot-dipped zinc handle wet winters and hot summers without loosening.

Tool Versatility for On-Site Efficiency

One coil nailer covers sheathing, framing, and blocking jobs. Crews carry fewer tools and finish faster.

Optimizing Cable Tray Fabrication Through Coil Nails

Cable tray lines must turn out hundreds of meters every shift, and every second counts.

Precise Metal-to-Wood Fixation

Shanks between 2.5 mm and 3.3 mm drive straight through metal rails into wooden supports. Wood rarely splits, and trays stay perfectly aligned.

Corrosion Protection for Harsh Environments

Mechanical galvanizing spreads an even, thick layer that fights dampness and chemicals inside factories or data centers.

High-Volume Production Support

Wire collation almost never jams, even when the gun runs at full speed. The line keeps rolling without annoying stops.

Accelerating Container Flooring Assembly with Coil Nails

Container floors take brutal punishment from forklifts and ocean waves year after year.

Heavy-Duty Penetration Capability

Thick 3.3 mm shanks in 90-120 mm lengths sink deep into 28 mm plywood and lock it firmly to steel beams underneath.

Galvanized Durability for Marine Use

Hot-dipped coating shrugs off saltwater and wet weather. Floors stay strong for the full life of the container.

Efficient Workflow Integration

One person with a coil nailer often finishes a whole floor before a hammer team completes half. Time savings add up quickly.

Streamlining Fencing and Railing Projects via Coil Nails

Large fencing contracts stretch across fields or property lines for kilometers.

Rapid Post and Rail Installation

Ring shank coil nails from 50 mm to 80 mm long grab treated timber hard. Wind, cattle, or kids leaning on the fence cannot loosen them.

Aesthetic and Functional Finishes

Colored coatings match stained or painted wood, so the fence looks clean and professional from day one.

Scalable for Large-Scale Deployments

Full coils mean crews walk less and nail more. Big ranch jobs or housing development perimeters go up in record time.

Why Choose Qinjia for Your Coil Nails Supply Needs?

You want a partner who ships on schedule, meets every spec, and fixes problems fast when they appear. Qinjia delivers exactly that, every single time.

Proven Quality Assurance Processes

Every batch goes through strict hardness tests, salt spray tests, and full size checks before packing. Reports from SGS or BV are ready the moment you ask, so you never worry about quality surprises.

Tailored OEM/ODM Customization

Change the shank, head, point, finish, or even box design through the special OEM/ODM service. Small trial runs start at just one pallet, letting you test everything in your own factory before ordering full containers.

Global Export Expertise and Support

-

Simple 30/70 payment terms, detailed photos and videos before loading, fast replies within hours, and direct help through contact-us keep every order smooth from first quote to final delivery.

-

Experienced team handles sea freight, air freight, or express so your nails arrive on time, anywhere in the world.

With Qinjia, you get reliable supply, zero headaches, and a true partner who cares about your business success.

FAQ

Q1: Which coil nail shank gives the strongest holding power?

A: Screw shank wins for maximum grip, with ring shank a close second. Both beat smooth shank by 30-50 percent.

Q2: Can the same coil nails work for pallets and house framing?

A: Yes. Pick the right length and diameter, and one high-quality coil handles pallets, framing, fencing, and more.

Q3: How long do hot-dipped galvanized coil nails last outside?

A: Ten to fifteen years is normal in most weather. The thick zinc layer protects far longer than thin electro-galvanized coating.