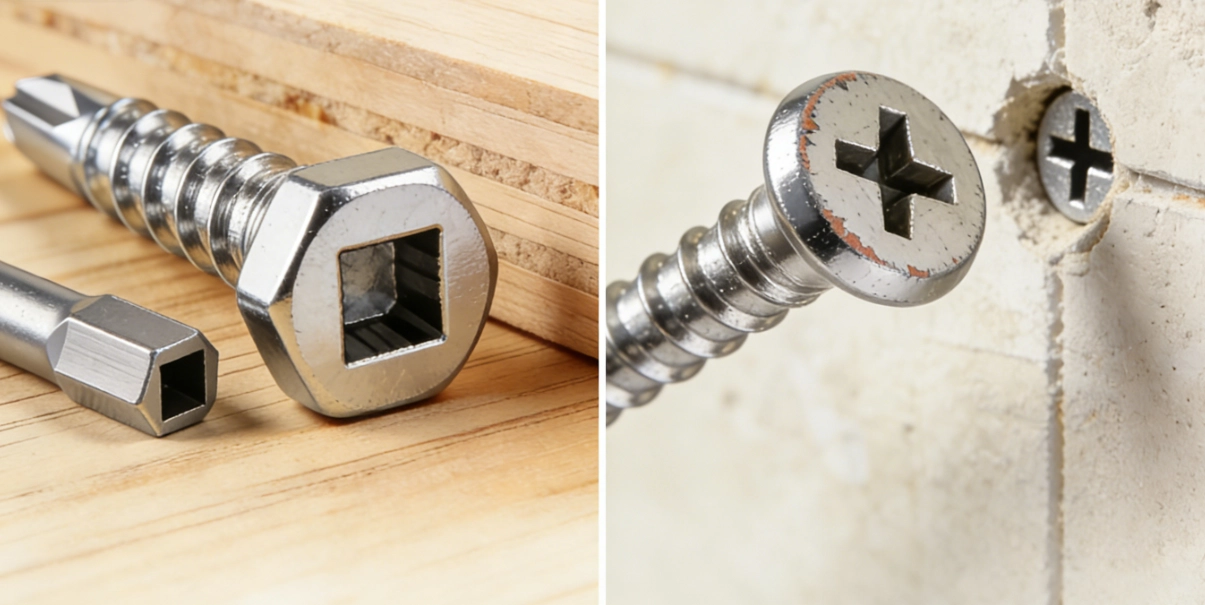

Square Drive Drywall Screws vs. Phillips: Which Offers Better Grip

When you’re standing on a ladder, balancing a heavy sheet of gypsum board with one hand and a drill in the other, the last thing you want is for your screw to slip. That split-second “skit” across the board doesn’t just ruin the finish; it kills your momentum. In the world of construction and timber work, the debate between drive types isn’t just for hardware geeks—it’s about how fast you can finish a job without stripping your bits.

At Qinjia , we’ve spent years manufacturing fasteners for the North American and Middle Eastern markets. We see firsthand how choosing the right drive type—whether it’s the classic Phillips or the increasingly popular Square drive—changes the game for contractors on the ground.

I. Understanding Phillips Drive Drywall Screws

For decades, the Phillips head has been the “old reliable” of interior partition walls. If you walk into any job site from New York to Istanbul, you’ll find buckets of these. Our standard Drywall Screws are designed with this cross-head pattern because it’s what most pneumatic and electric tools are already set up for.

The Phillips design actually has a built-in “safety” feature that many people don’t realize: it’s designed to “cam out.” This means the bit is supposed to pop out of the head when the screw meets enough resistance. In the early days of automated assembly, this prevented workers from snapping the screw or over-driving it deep into the soft gypsum core. Our bugle-head Phillips screws are perfect for this—they sit flush against the paper without tearing it.

However, the downside is obvious to anyone who’s ever been in a rush. If you don’t apply enough pressure, or if your bit is even slightly worn, the Phillips head strips easily. It’s frustrating, it wastes material, and it’s the number one reason why some pros are making the switch to something more “grippy.”

II. Exploring the Advantages of Square Drive (Robertson) Screws

If Phillips is about controlled slipping, the Square Drive (often called the Robertson) is all about raw grip. The square socket is deep and has four flat sides that provide a massive amount of surface area for the driver bit to grab onto.

When we manufacture Chipboard Screws or specialized timber fasteners, we often recommend the square drive for a simple reason: torque transfer. You don’t have to push nearly as hard to keep the bit engaged. In fact, you can often “stick” a square drive screw onto the end of your bit and it will stay there—even if you’re reaching sideways or overhead. It makes one-handed installation actually possible, which is a lifesaver when you’re working in tight corners or ceiling systems.

For heavier materials, like the dense woods often used in furniture or high-density chipboard, the square drive is vastly superior. It won’t strip out, meaning you can drive it in and out multiple times if you need to adjust your framing without ruining the screw head.

III. Comparative Analysis: Grip, Speed, and Durability

So, which one actually performs better when the pressure is on? Let’s break it down based on what we see in our testing lab in Hebei.

-

Torque Performance: In our factory, we use handheld torque testers and tapping speed machines to check how our screws hold up. The Square drive wins on torque every time. Because the bit won’t “cam out,” you can put much more power behind the drill.

-

Installation Speed: This is a toss-up. Phillips is faster to “find” with the bit because it has more entry points (the cross shape). You can just jam the bit in and go. Square drives require you to align the square bit exactly, which takes a half-second longer. But, you make up that time by not having to deal with stripped heads.

-

Tool Life: Square drive bits tend to last longer. Since they don’t slip and grind against the metal of the screw, they don’t wear down as fast as Phillips bits do.

IV. Choosing the Right Screw for Your Project

Selecting between these two depends entirely on what you’re building. There isn’t a “one size fits all” answer, even though we’d love to sell you a million of both.

If you’re doing a standard interior drywall job with light steel or wood studs, stick with the Phillips Drywall Screws. This aligns with the broader North American drywall fasteners market, valued at $24.76 billion in 2023 (including hooks and boards), projected to grow at a CAGR of 11.2% from 2024 to 2030. They are cost-effective, everyone has the bits, and they are designed to work perfectly with the soft nature of gypsum board. Our black phosphated or zinc-plated versions give you that extra rust resistance you need for damp construction environments.

On the other hand, if you’re working on cabinetry, heavy-duty furniture, or multi-layer chipboard, go for the Square Drive. The extra grip ensures that you can pull the wood pieces tight together without the screw head turning into a useless metal circle. It’s also the better choice for outdoor projects where you might be wearing gloves and can’t fiddle with a slipping Phillips bit. Related self-drilling screws, often featuring enhanced drives like Square for better torque in tough materials, saw a global market of $747.8 million in 2022, growing at a CAGR of 5.4% from 2023 to 2030.

V. Quality Assurance at Qinjia

No matter which drive you choose, the screw is only as good as the steel it’s made from. At Qinjia, we don’t just “make” screws; we control the whole process. From the moment the raw wire arrives at our facility to the final heat treatment, we’re checking for hardness and dimensions.

We know that a “cheap” screw is actually the most expensive thing on a job site because it breaks, it rusts, and it slows down the crew. That’s why we offer third-party inspections (like SGS or BV) and provide full material certificates for our global partners. Whether you need 18GA brad nails for finishing or heavy-duty ST nails for concrete, we ensure the heat treatment is spot on so the heads don’t snap off under pressure.

VI. Conclusion

At the end of the day, the “better” grip belongs to the Square drive, but the “standard” remains Phillips for a reason. If you want maximum efficiency and the ability to work one-handed, give the square drive a shot on your next timber or chipboard project. But for the bread-and-butter of interior walls, a high-quality Phillips drywall screw from a reliable supplier like Qinjia will never let you down.

Check out our full range of fasteners at our site to see how we can support your next big project with bulk supply and custom OEM packaging.

FAQ

Q1: Can I use a Phillips bit on a Square drive screw in an emergency?

A: No. They aren’t compatible at all. Attempting to use a Phillips bit will instantly strip the square socket and likely ruin your driver bit. Always match the tool to the drive type.

Q2: Why are Qinjia’s drywall screws usually black?

A: Most of our drywall screws undergo a black phosphated treatment. This isn’t just for looks; it provides a great surface for joint compound (mud) and paint to stick to, while offering basic corrosion protection during the construction phase.

Q3: Does Square drive cost significantly more than Phillips?

A: Slightly, yes. The manufacturing process for the square socket is a bit more demanding on the headers, and the market volume is lower than the universal Phillips. However, for many pros, the money saved on wasted screws and faster labor more than makes up for the small price gap.