Expert Advice on Nail Gun Nails: Choosing Correct Fixings for Wood, Brick & Plaster

Choosing the right nail gun nails often looks simple on the surface. In real projects, it is one of the most common reasons for loose fixings, cracked materials, or repeated rework. Different base materials react very differently to impact, pressure, and holding force. A nail that performs well in timber may fail fast in brick or plaster.

For distributors, contractors, and project buyers, understanding nail selection is not about brand names or tools alone. It comes down to matching material hardness, nail structure, and driving method. As a manufacturer with a full range of fastening products, Qinjia works closely with overseas markets to solve these practical issues on site, not just on paper.

Why Does Choosing the Right Nail Gun Nail Matter for Different Materials?

Before getting into product types, it helps to understand why material-based nail choice is so important. Wood, brick, and plaster all behave differently once force is applied. This is where many installation problems begin.

Material-Specific Holding Strength

Wood fibers compress and recover. Brick and concrete resist penetration but may crack under wrong pressure. Plasterboard is brittle and fails easily when overloaded. Each surface needs a different balance between hardness, shank diameter, and penetration depth.

Qinjia’s product range is designed around this reality. High-carbon concrete nails focus on penetration strength. ST nails use thicker shanks to handle framing loads. Brad nails stay slim to avoid splitting wood or damaging surface finishes.

Ignoring these differences often leads to nails backing out, snapping, or pulling loose over time.

Between understanding the base material and choosing the nail, the next factor comes from the tools used on site.

Tool Compatibility and Installation Safety

Not every nail works safely in every nail gun. Pneumatic nail guns, gas-actuated tools, and manual systems all apply force differently. A mismatch can cause bent nails, surface blowouts, or even tool damage.

Qinjia designs nail lengths, head styles, and shank profiles to stay compatible with common pneumatic and gas-driven systems used in North America, the Middle East, and Australia. This reduces jobsite risks and helps crews keep a steady work rhythm without constant tool adjustment.

Long-Term Fixing Performance

Short-term holding power is only part of the story. Poor nail selection often shows problems months later: trim loosening, wall panels shifting, or fixtures rattling.

Using nails that match both material and load keeps fixings tight over years, not weeks. This is especially important for commercial interiors, housing projects, and prefabricated construction where callbacks cost real money.

Which Nail Gun Nails Work Best for Wood Applications?

Wood remains one of the most common building materials worldwide. From structural framing to furniture and interior finishing, nail choice changes with load and appearance.

Structural Framing with ST Nails

ST nails are built for serious fixing jobs. Made from heat-treated 45# steel, they feature a thicker shank and high bending resistance. These nails are widely used for fixing wood studs or light steel frames directly to concrete or brick walls.

In many markets, ST nails replace traditional drive pins in interior framing. They work with pneumatic nail guns, avoid powder loads, and allow faster, cleaner installation. Qinjia supplies ST nails in multiple lengths to match framing depth and wall conditions.

Finishing and Trim with Brad Nails

Brad nails are the go-to choice for visible woodwork. With common sizes in 18GA and 16GA, they provide enough holding power for trims, frames, and light assemblies without leaving large holes or splitting thin boards.

Qinjia brad nails are widely used in furniture production, door and window trim, and decorative panels. Their smooth surface and consistent straightness help reduce jamming and surface marks, which matters a lot in finishing work.

For softer materials and high-frequency fastening, another option often comes into play.

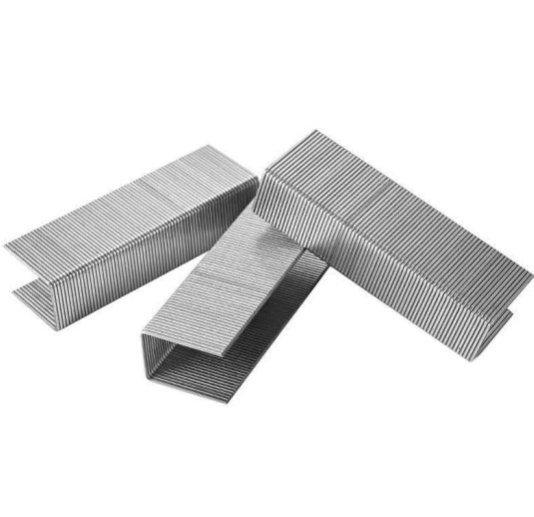

Upholstery and Light Wood Fixing with Staples

Staples are ideal for non-structural wood applications where speed matters more than deep penetration. Upholstery, soft panels, packaging frames, and thin boards all benefit from fast staple installation.

With multiple crown widths and leg lengths, Qinjia staples allow users to choose just enough grip without damaging surface materials. They are especially popular in furniture factories and interior workshops running high daily output.

How Should Nails Be Selected for Brick and Concrete Walls?

Hard surfaces like brick and concrete demand a different mindset. Here, penetration ability and material toughness take priority over appearance.

Direct Fixing with Concrete Nails

Concrete nails are a traditional solution that still works well in many cases. Made from high-carbon steel and heat treated, they are designed to penetrate masonry without bending.

Qinjia concrete nails are available with zinc plating, bluing, or phosphated finishes, making them suitable for both indoor and outdoor use. They are often chosen for base fixing, temporary structures, or smaller installations where nail guns are not practical.

When project speed and consistency are critical, contractors often move toward powered systems.

High-Efficiency Fastening with Gas Drive Pins

Gas drive pins offer fast, repeatable fixing into concrete and steel. Used with gas-actuated nail guns, they significantly cut installation time on large projects.

Qinjia gas drive pins are designed for reliable penetration and stable holding in hard substrates. They are commonly used in steel structures, concrete walls, and commercial interiors where productivity matters. In framing situations, another nail type bridges the gap between wood and concrete.

Stud Installation Using ST Nails

ST nails are widely used to secure wood or light steel studs directly into masonry. Compared to gas drive pins, they offer better control in interior framing and avoid the need for powder loads.

Their thicker diameter helps maintain alignment and reduces the risk of pull-out, especially in partition wall systems and renovation projects.

What Are the Best Nail Choices for Plaster and Drywall Systems?

Plasterboard and drywall systems need a careful balance. Too much force causes cracking. Too little leads to loose boards.

Secure Drywall Fixing with Drywall Screws

Drywall screws remain the main fixing method for plasterboard systems. With sharp threads and bugle heads, they sit flush without tearing the board surface.

Qinjia supplies both coarse-thread screws for wood studs and fine-thread versions for light steel framing. This clear separation helps installers avoid common mistakes that weaken wall systems.

Light Fixing and Edge Work with Brad Nails

Brad nails are often used for trims, edge work, and decorative elements around drywall systems. Their thin profile lowers the risk of cracking plaster edges.

They are not load-bearing fasteners, but they work well when combined with adhesives or screws for finishing tasks.

Cable and Pipe Fixing with Pipe Hook Nails

Pipe hook nails provide a simple solution for cable management and small-diameter pipe installation. The integrated plastic hook holds lines in place while the steel nail secures into the wall.

Qinjia pipe hook nails are commonly used in residential wiring, HVAC support, and light plumbing work. UV-resistant plastic options allow limited outdoor use as well.

How Can Qinjia Nail Gun Nails Improve Project Efficiency and Reliability?

Beyond individual products, consistency and supply reliability matter just as much to buyers and contractors.

Consistent Quality Control

Qinjia operates full-process quality checks from raw material intake to final packaging. Hardness testing, size inspection, and surface finish control help keep performance stable from batch to batch.

For overseas buyers, this consistency reduces complaints, returns, and on-site surprises.

Wide Product Range for One-Stop Sourcing

From concrete nails and ST nails to brads, staples, gas drive pins, and drywall screws, Qinjia covers most common fastening needs. This allows distributors and project buyers to source multiple items from one supplier, simplifying logistics and inventory planning.

OEM Support and Market Adaptability

Different markets prefer different packaging, finishes, and specs. Qinjia supports OEM branding, customized packaging, and sample development to match regional demand.

This flexibility has helped the company build long-term partnerships across North America, the Middle East, Southeast Asia, and Australia.

FAQ

Q1: Can one nail type work for wood, brick, and plaster?

A: Not really. Each material behaves differently. Using a “one-size-fits-all” nail usually leads to weak holding or surface damage. Matching nail type to material gives far better results.

Q2: Are ST nails the same as drive pins?

A: No. ST nails are used with pneumatic nail guns and do not rely on powder or gas cartridges. Drive pins are designed for powder-actuated or gas tools and work differently.

Q3: How do surface finishes affect nail performance?

A: Surface treatments like zinc plating or phosphating improve corrosion resistance. This matters for outdoor use, humid environments, or long service life requirements.