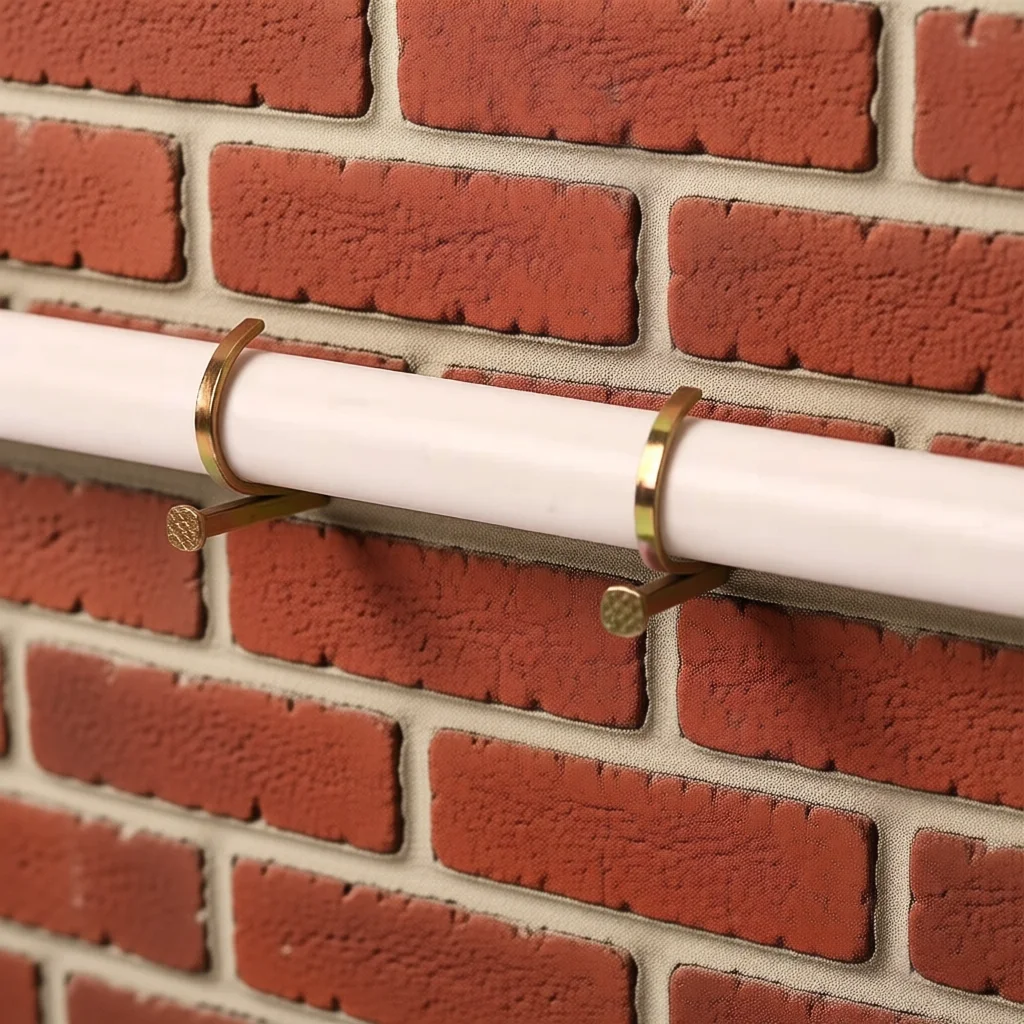

Model:

| Model |

Diameter |

Hook Size |

Fitting Pipe Size |

DN Reference |

Pcs/Box |

Box/ctn |

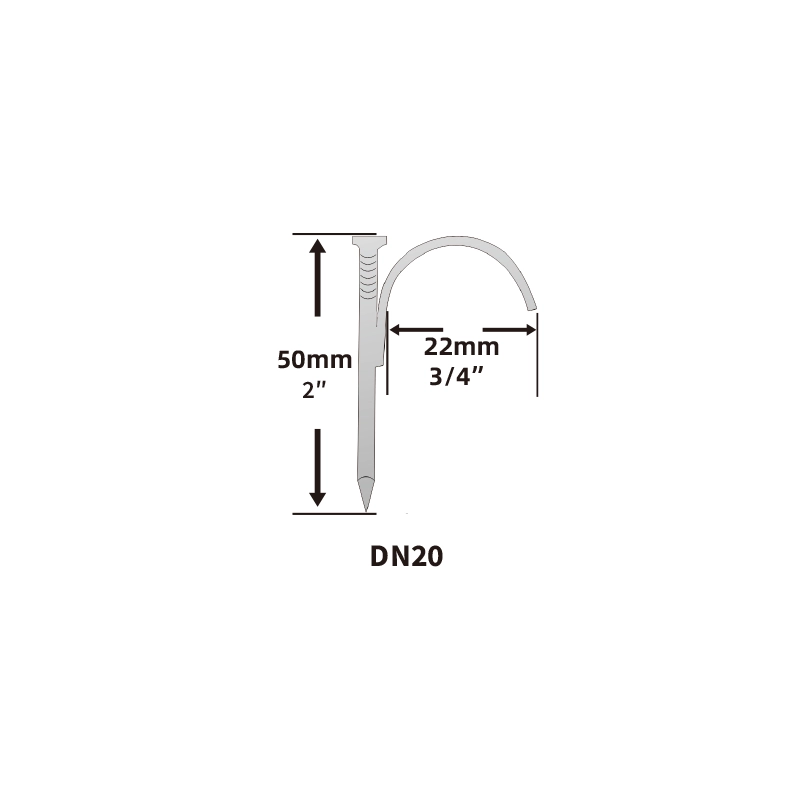

| JH-20 |

3.3 mm |

20 mm |

3/4″ Pipe |

DN 20 |

200 |

10 |

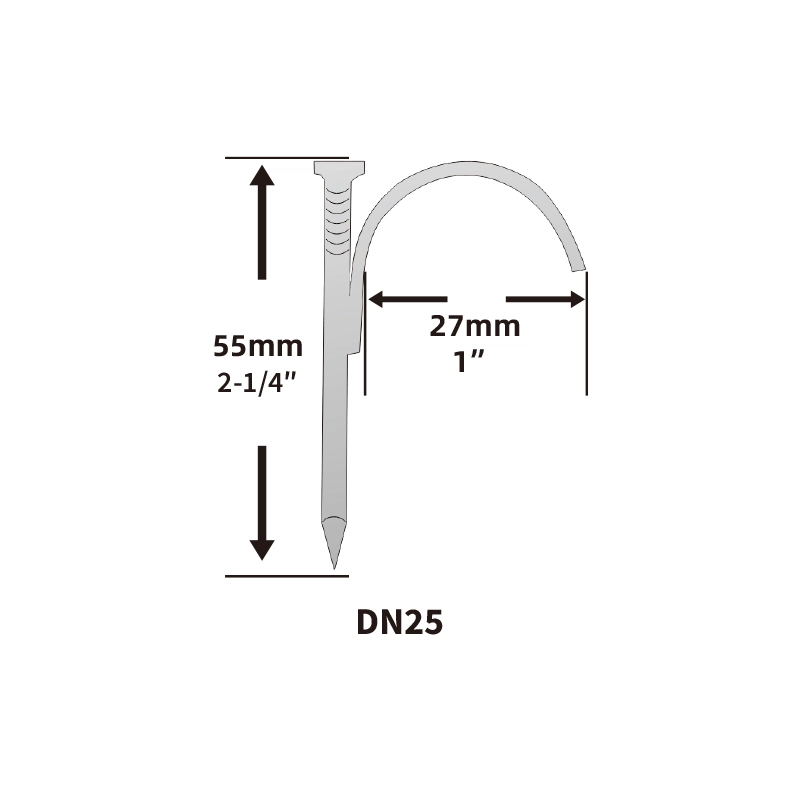

| JH-25 |

3.3 mm |

25 mm |

1″ Pipe |

DN 25 |

200 |

10 |

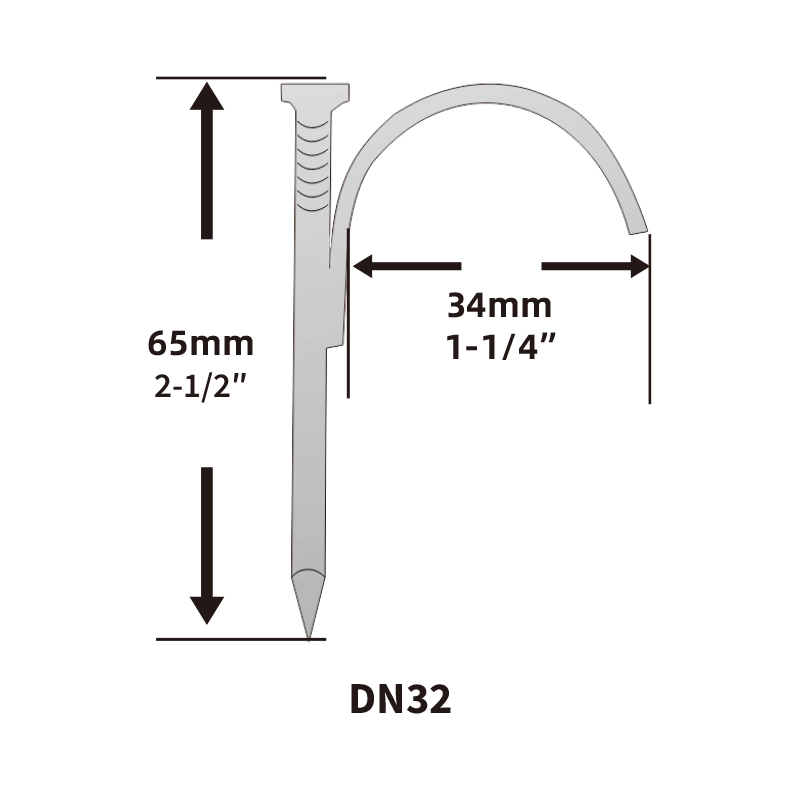

| JH-30 |

3.3 mm |

32 mm |

1-1/4″ Pipe |

DN 32 |

200 |

10 |

Application:

J hook nails are primarily used for fixing water pipes, electrical conduits, and cable lines onto concrete or masonry surfaces.They are commonly applied in residential, commercial, and industrial installations where organized and secure pipe or conduit routing is required.

J Hook Nails – FAQ

1: What are J hook nails mainly used for?

J hook nails are mainly used for fixing water pipes and electrical conduits onto concrete or masonry surfaces. They are commonly applied in plumbing and electrical installation projects.

2: What pipe sizes are supported by your J hook nails?

We offer three standard sizes:

• 20 mm – suitable for DN20

• 25 mm – suitable for DN25

• 32 mm – suitable for DN32

These sizes cover most common water pipe and conduit installations.

3: Are J hook nails suitable for both water pipes and electrical conduits?

Yes. J hook nails can be used for fixing water pipes, PVC conduits, and other cable routing systems.

4: What materials are J hook nails made from?

Our J hook nails are manufactured from carbon steel and processed with heat treatment to ensure sufficient strength and stable performance.

5: What surface finishes are available?

Common finishes include galvanized and other corrosion-resistant surface treatments. Custom finishes can be provided for bulk orders.

6: Are J hook nails suitable for concrete installation?

Yes. They are designed for installation into concrete and masonry substrates.

7: Can packaging be customized for wholesale orders?

Yes. We support bulk packaging, small box packing, and customized private label packaging for wholesale and OEM customers.

8: Do you support bulk export orders?

Yes. J hook nails are supplied for bulk export with stable production and consistent specifications.

Additional Services

• Customized packaging and labeling according to customer requirements

• Consistent surface finish and appearance control across production batches

• Export documentation support including packing list and HS code declaration

• Stable supply capability for bulk orders with confirmed specifications

• OEM and private label support for distributors and wholesalers

Why Choose Us?

1.Experienced Manufacturer

With over 20 years of manufacturing experience, we specialize in the production of concrete nails and industrial fasteners for international markets.

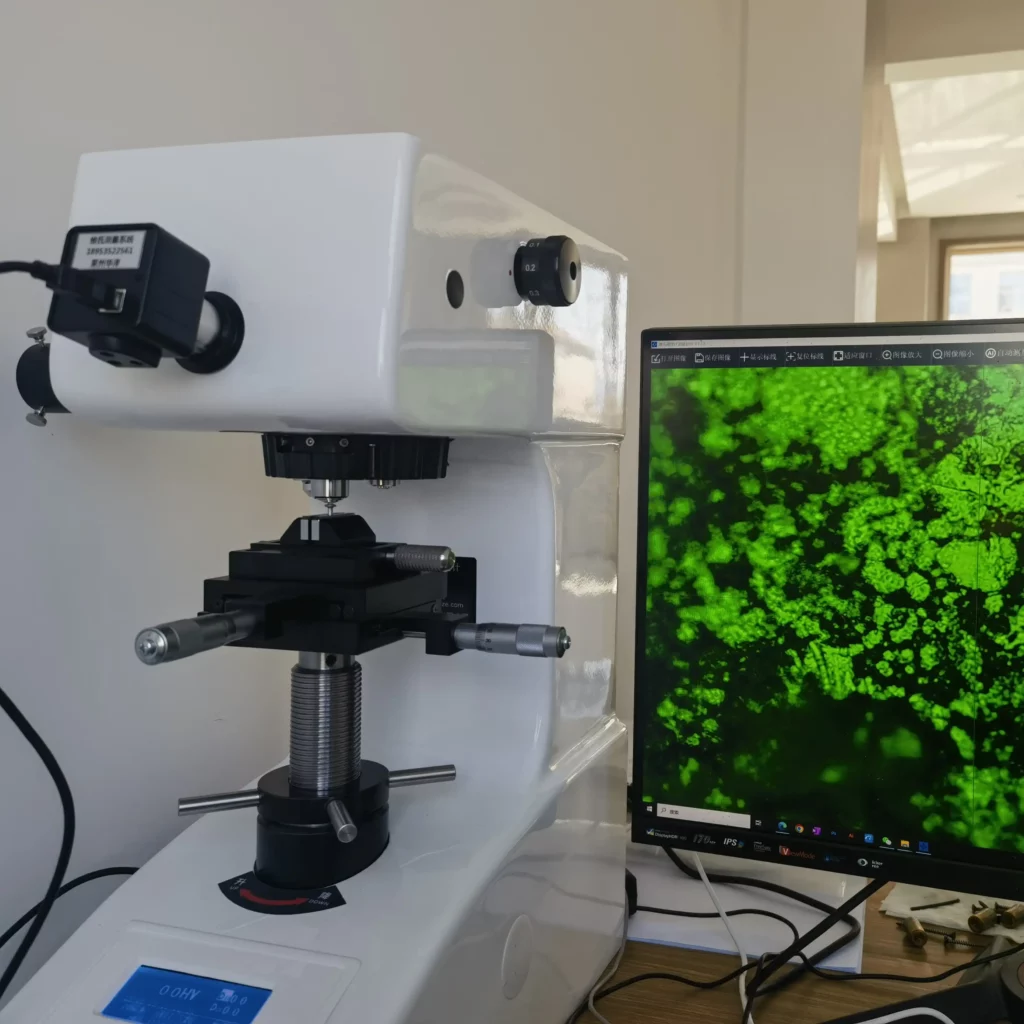

2.Complete Quality Control System

From wire drawing to finished nails, every production stage is monitored with dedicated inspection equipment. Hardness testing, dimensional checks, and process control ensure stable and consistent quality.

3.In-House Production & Stable Capacity

Equipped with cold heading machines, heat treatment lines, and surface finishing facilities, we support continuous production and reliable supply for bulk and repeat orders.

4.Flexible OEM & Customization Support

We offer customization in size, surface finish, packaging, and private labeling to meet different market and customer requirements.

5.Export-Oriented Supply Experience

Familiar with export standards, packing specifications, and international logistics, we provide efficient support for wholesalers, distributors, and long-term partners.

Manufacturing Facility & Quality Control

Selected views of our production process, quality inspection, and shipment preparation for wholesale orders.