Model:

| Model |

Shank diameter |

Length |

Single weight |

| mm |

inch |

mm |

inch |

| CMG25 |

2.6mm |

0.102″ |

25mm |

1″ |

1.02g |

| CMG30 |

2.9mm |

0.114″ |

30mm |

1-3/16″ |

1.4g |

| CMG40 |

3.2mm |

0.126″ |

40mm |

1-5/8″ |

2.51g |

| CMG50 |

3.5mm |

0.138″ |

50mm |

2″ |

3.79g |

| CMG60 |

3.7mm |

0.146″ |

60mm |

2-3/8″ |

5.28g |

| CMG70 |

4.1mm |

0.161″ |

70mm |

2-3/4″ |

7.42g |

| CMG80 |

4.5mm |

0.177″ |

80mm |

3-3/16″ |

10.37g |

| CMG100 |

4.8mm |

0.185″ |

100mm |

4″ |

14.06g |

| CMG130 |

5.0mm |

0.197″ |

130mm |

5-3/16″ |

21g |

| CMG150 |

5.0mm |

0.197″ |

150mm |

6″ |

23.36g |

Application:

Concrete nails are widely used in construction and building applications for fastening materials into concrete, brick, and masonry surfaces.

They are commonly applied in:

• Fixing wooden battens, strips, and frames onto concrete walls

• General construction and renovation projects

• Attachment of auxiliary components in building structures

• Brick and masonry fastening applications

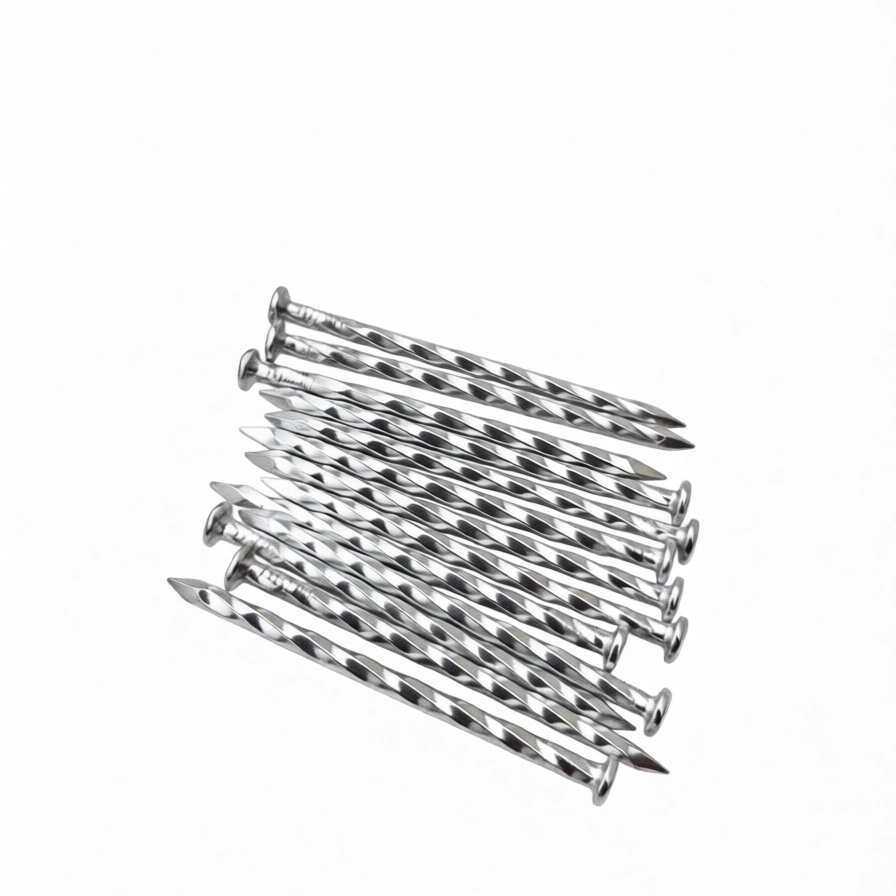

Concrete Nails Grooved(Fluted)Shank – FAQ (For Wholesalers & Importers)

1. What are grooved shank concrete nails mainly used for?

Grooved shank concrete nails are used for the same construction applications as smooth shank concrete nails, including fastening into concrete, brick, and masonry surfaces.

They are commonly applied in:

• General building construction

• Fixing wooden components onto concrete

• Frames, battens, and structural attachments

The grooved shank design is chosen when additional holding stability is required.

2. What is the difference between smooth shank and grooved shank concrete nails?

Smooth and grooved shank concrete nails serve the same purpose, but differ in shank structure.

• Smooth shank concrete nails

Preferred when easier driving and faster installation are required.

• Grooved shank concrete nails

Selected when better grip and reduced loosening are needed, especially in harder concrete or vibration-prone conditions.

The choice depends on job conditions rather than application type.

3. What raw materials are used for your grooved shank concrete nails?

Our grooved shank concrete nails are made from high carbon steel, with controlled heat treatment to ensure balanced hardness and toughness for concrete fastening.

4. Are grooved shank concrete nails suitable for bulk export orders?

Yes. Grooved shank concrete nails are widely supplied in bulk export orders and are often ordered together with smooth shank concrete nails for different customer preferences.

They offer stable production quality and consistent batch performance.

5. What surface finishes are available?

Surface finish options are the same as smooth shank concrete nails:

• Bright (plain finish)

• Coating with color(Blue/Black)

• Galvanized for corrosion resistance

Other finishes are available upon request.

6. What packaging options do you provide?

We provide the same flexible packaging options:

• Small boxes + cartons

• Bulk packing

• Customized OEM and private label packaging

7. What is your MOQ for grooved shank concrete nails?

MOQ depends on size and packaging.

For wholesale and long-term partners, we offer flexible MOQ arrangements.

8. Can grooved shank concrete nails be customized?

Yes. Customization options include:

• Length and diameter

• Groove pattern

• Head type

• Surface finish

• Packaging and labeling

Additional Services

To support wholesale buyers and long-term partners, we provide the following additional services for concrete nails:

• Customized packaging and labeling according to customer requirements, including private label and OEM solutions

• Consistent surface finish and appearance control across production batches to ensure uniform quality for bulk supply

• Export documentation support, including packing list preparation and HS code declaration for international shipments

• Stable supply capability for bulk orders with confirmed specifications, ensuring on-time production and delivery

• OEM and private label support for distributors, wholesalers, and brand owners

Why Choose Us?

1.Experienced Manufacturer

With over 20 years of manufacturing experience, we specialize in the production of concrete nails and industrial fasteners for international markets.

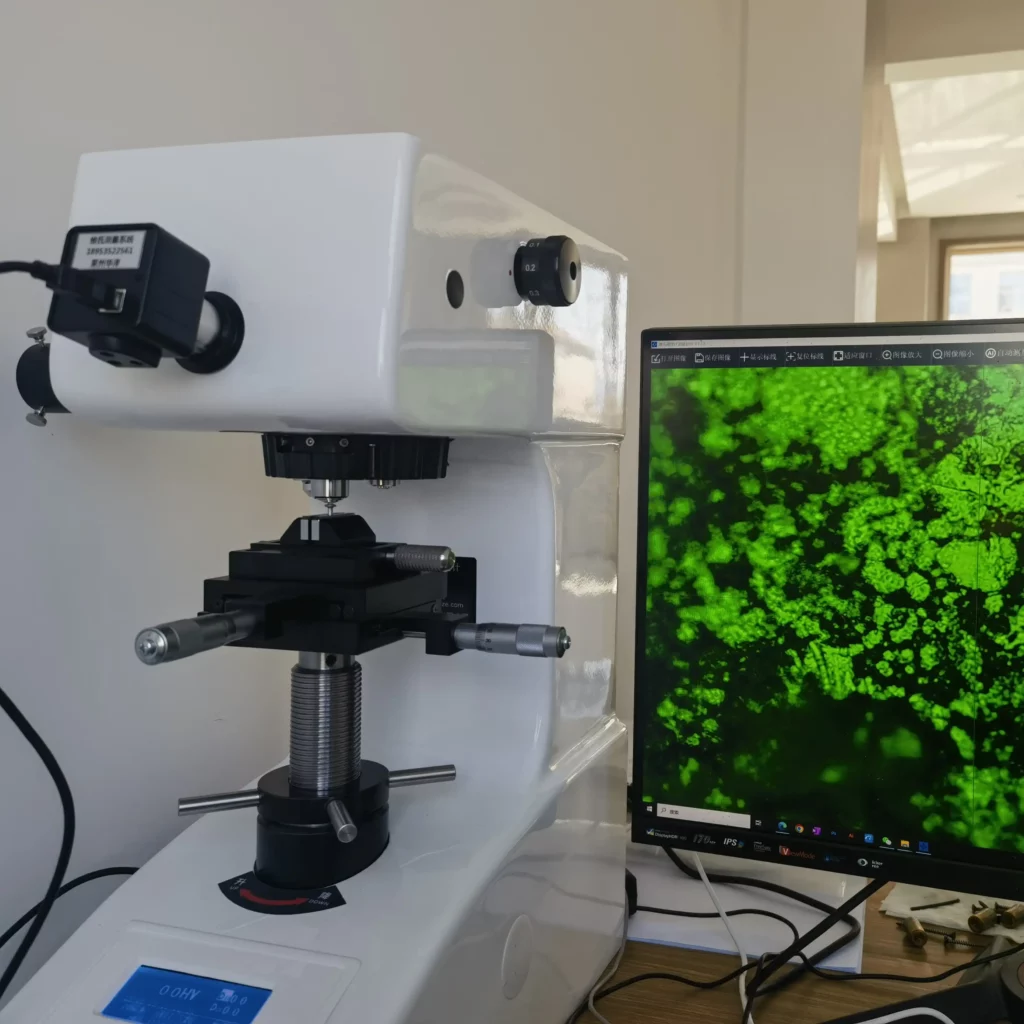

2.Complete Quality Control System

From wire drawing to finished nails, every production stage is monitored with dedicated inspection equipment. Hardness testing, dimensional checks, and process control ensure stable and consistent quality.

3.In-House Production & Stable Capacity

Equipped with cold heading machines, heat treatment lines, and surface finishing facilities, we support continuous production and reliable supply for bulk and repeat orders.

4.Flexible OEM & Customization Support

We offer customization in size, surface finish, packaging, and private labeling to meet different market and customer requirements.

5.Export-Oriented Supply Experience

Familiar with export standards, packing specifications, and international logistics, we provide efficient support for wholesalers, distributors, and long-term partners.

Manufacturing Facility & Quality Control

Selected views of our production process, quality inspection, and shipment preparation for wholesale orders.