How Can Staple Optimize Cross-Department Collaboration and Output

In construction and woodworking, staples are the unsung heroes that keep projects moving across teams. You’ve seen it: carpenters frame, upholsterers finish, and assemblers tie it together, but poor fasteners cause delays and rework. Quality staples fix that by speeding up handoffs and cutting errors. A solid choice is sourcing from Qinjia, a Hebei-based veteran in fasteners since the 1990s. They focus on nails and screws for building and woodwork, exporting to North America, the Middle East, Australia, Southeast Asia, and Turkey. Their supply chain is rock-solid, with rigorous quality checks from raw materials to final shipment.

What Role Do Staples Play in Construction Projects?

Staples handle a range of tasks, from securing soft packs to fixing thin boards, ensuring teams pass work along without hiccups. They complement concrete nails for brick walls or gas drive pins for steel, tying departments together seamlessly.

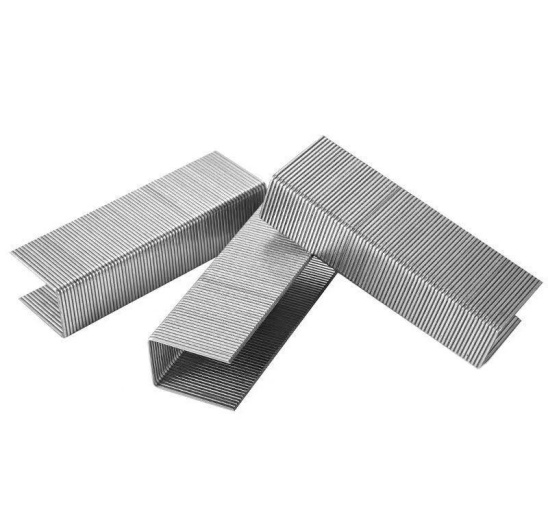

Versatile Fastening Solutions

Choose from series like 80, 90, or 92, with leg lengths up to 50mm, perfect for upholstery or packaging. These adapt to indoor or outdoor jobs, keeping your workflow flexible.

High-Durability Materials

Made from low or medium carbon steel, staples resist bending in tough spots. They hold strong, much like brad nails that prevent splits in furniture or frames.

Tool Compatibility Features

Staples work with various staple guns, speeding up tasks like soft package fixes. This compatibility boosts efficiency, outpacing manual hammering in busy schedules.

How Can Staples Boost Woodworking Efficiency?

In woodworking, delays from one team can stall others, but staples keep things moving with quick holds in frames or finishes. For furniture or decor, products like 16 Gauge 1 Inch Crown Staples offer wide crowns for strong grips on wood or fabrics, cutting time.

Reduced Assembly Time

Short legs starting at 6mm mean faster setups, letting carpenters hand off to finishers quickly. You save minutes compared to using screws or nails.

Minimized Material Waste

Precision designs reduce bent or discarded pieces, especially in bulk OEM packs. This keeps your costs down and materials in play.

Seamless Team Integration

Staples pair with pneumatic tools, syncing with drywall screws for partitions. Coarse-thread screws grab wood studs, streamlining department handoffs.

Why Select Staples for Global Trade?

For global deals, you need fasteners that pass customs and meet client specs without fail. Staples from trusted lines, backed by exports to the US or Australia, come with full inspections like hardness or salt spray tests.

Proven Export Experience

Years of shipping to Vietnam and South America build reliability. You get material proofs and packing lists to ease trade processes.

Custom OEM Options

Tailor staples for your brand, like galvanized coatings for humid markets. This flexibility helps you meet specific buyer needs.

Strict Quality Controls

Random checks and torque testers for related screws ensure high standards. Third-party tests like SGS are available if your clients demand them.

How Do Custom Staples Enhance Project Customization?

Your projects differ, from indoor walls to outdoor setups, and custom staples prevent mismatches that slow teams down. With series options, you tweak crowns or materials to fit specific guns or tasks.

Tailored Length Variations

Legs from 6 to 50mm suit thin boards or soft packs without excess. You match exact job specs, avoiding overkill.

Material Selection Flexibility

Pick low-carbon steel for light tasks or medium for tougher holds. This ensures durability across your project types.

Application-Specific Designs

Wide crowns grip fabrics in upholstery, while woodwork staples avoid cracks. You get fasteners that fit your crew’s needs.

What Benefits Come from ODM Services?

ODM lets you adapt fasteners to your market, fixing issues like rust in damp areas or weak holds in frames. This keeps your teams aligned, with innovations like C rings for nets or packaging.

Innovative Product Development

New designs, like heat-treated staples, match trends in gas-driven tools. You stay ahead with fasteners built for modern needs.

Branded Re-Selling Support

Custom packs for your label simplify resale to global clients. You streamline distribution without extra hassle.

Collaborative Design Processes

Work on samples or drawings to hit your specs, from sizes to coatings. This collaboration speeds up project planning.

How Can Staples Improve Upholstery and Finishing Tasks?

Upholstery work stalls when staples bend or pull out, slowing finishers waiting to polish. Products like 18 Gauge 92 Series 5/16 Inch Narrow Crown Staples offer narrow holds for frames or decor, gripping fabrics without pulls. Sometimes, a single bad staple can throw off your rhythm, but quality ones keep things moving.

Precision in Fine Work

Thin gauges prevent splits in delicate woods or fabrics. You get clean finishes for furniture or decor handoffs.

Durable Tensile Strength

High-carbon builds hold through transport or heavy use. This durability cuts down on rework across teams.

Efficient Bulk Packaging

Boxes of 400 to 2000 pieces reduce restock stops. OEM options keep your supply chain tight and organized.

Where to Source Reliable Staples for Optimized Output?

You need suppliers with fast shipping options and full support, from quotes to after-sales. Look for those handling mixed containers or offering return policies based on quality checks with photos or videos.

Direct Factory Contacts

Reach out for quotes or samples to kick off production. Quick responses keep your project timelines on track.

Case Study Insights

Real examples, like cable fixes with pipe hooks or drywall setups, show cost and time savings. These prove staples’ value in big jobs.

Comprehensive Service Support

Tech guides and parts supplies keep your operations smooth. Feedback-driven tweaks ensure long-term reliability.

FAQ

Q1: Can staples handle concrete or brick surfaces?

A: They’re better for soft materials like wood or fabric, but pair them with concrete nails for hard surfaces. High-carbon, heat-treated nails grip brick walls well.

Q2: How do staples stack up against gas drive pins for speed?

A: Staples install quickly with standard guns, but gas drive pins, with 12-62mm lengths, are faster for steel or concrete. They’re built for high-efficiency tools.

Q3: What if staples rust in outdoor projects?

A: Choose galvanized or phosphated versions for better rust resistance. These coatings handle humid or wet conditions effectively.